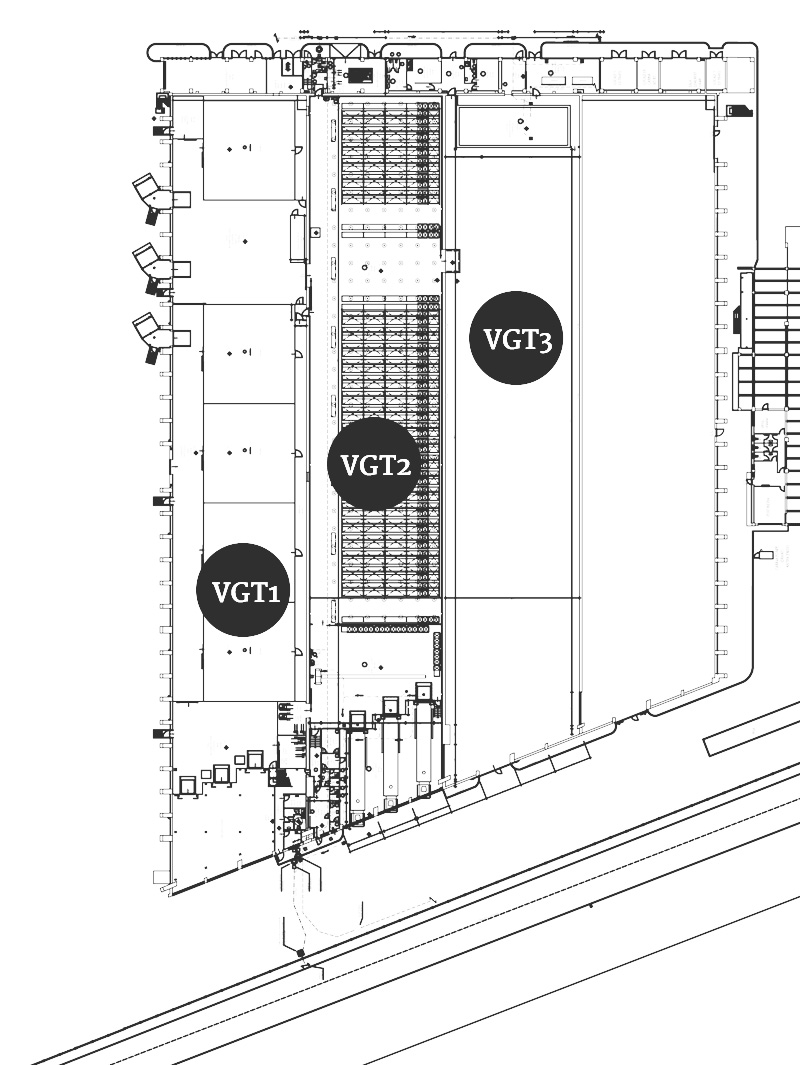

The Facility

Venice Cold Stores consists of three large bays (VCS1, VCS2, VCS3) that host different spaces for the storage and preservation of goods. Overall, the available surface is ten thousand square meters with 7 thousand fridge pallet spaces (EPAL). Thanks to its refrigerating machineries, VCS can store products at ten different temperatures.

VCS has 9 bays for simultaneously loading/unloading trailers and containers. The administrative offices of the terminal are located on the first floor of the building.

VCS 1

The 3,500 square meters of VCS1 accommodate 5 refrigerating rooms, each of which can work at a different temperature, and therefore accommodate individual product types that require specific storage conditions.

The facility of VCS1 is ideal for the storage of particularly delicate products. The rooms have a system of goods traceability and of monitoring of their storage conditions.

Inside the facility there are spaces for the movement of the products, for the palletisation, selection and bagging operations.

VCS 2

VCS2 is designed and structured to facilitate the picking of products. It is a large temperature-controlled room of 3,500 square meters and a total of 5 thousand pallet spaces (EPAL): the five-storey shelves are automated and allow fast and efficient management for each product.

VCS2 was completed and has been operational since summer 2014. The management of stored products is done via ID/REF Number and guarantees a complete internal traceability system.

VCS 3

VCS3 is the third large bay of the terminal: it is dedicated to logistics and traditional warehousing.

It has a total area of 3,500 square meters available for all those products that do not require particular temperature conditions to be stored. In particular, the structure is suitable for the storage of white lines.

Machinery

Venice Cold Stores is a modern facility, built thanks to a major investment in infrastructure and technology. In addition to a system of product monitoring and traceability, it has a highly efficient refrigeration system. Indeed, VCS refrigerating rooms are powered by a refrigeration unit of 4,800 kW overall. This makes it possible to guarantee that the products are stored at a wide temperature range (ten in all).

The unit consists of three chillers of 1,600 kW each, able to work either in-line or alternately so as to cope with all the possible customer requirements and the needs of the single product stored in the different rooms of VCS.

For the products’ movement and management, VCS has a fleet of forklift trucks (traditional and retractable) and transpallets capable of working up to 10.50 meters in height.